Automotive

HLN manufactured rubber parts are used in transmissions, brakes, steering, clutch assemblies, engines, air conditioning systems, batteries, electric motors, solenoid valves and in scores of other automotive rubber applications, as well as the automotive after market.

Power Steering Seals

Noise, Vibration & Harshness Control

Power Steering Hoses

Headlight Seals

Brakes & Modules

Head Gaskets

Engine Gaskets & Seals

Transmission Seals

Engine Mounts / Chassis

Fuel Systems

HVAC & Cooling Systems

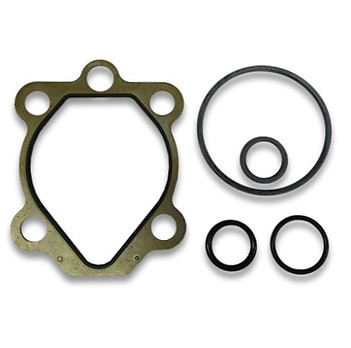

POWER STEERING SEALS

HLN understands the need for high percision and calibrates its design, formulation and production accordingly. For instance, many of the power steering applications of today use high-pressure hydraulic systems. Seals for these applications include an input shaft seal and inner and outer rack seals. The input shaft seal also called a pinion seal are for shafts with slow oscillating rotation, and they have operating pressures that are more than 10-20 psi.

The outer rack seal and inner rack seal are reciprocating applications and can see pressures up to 1500 psi. Typical rack seals will have plastic PTFE back-up rings to prevent seal lip blowout.

POWER STEERING HOSES

HLN produces power steering hoses that are able to perform well under a number of different conditions, possesses high tolerances for oil, heat and ozone resistance to counter the demanding conditions of transmission and engine systems; and withstand high temperatures, and have the durability for long term life applications

NOISE, VIBRATION & HARNESS CONTROL

HLN offers an array of automotive rubber to metal vibration isolators which are designed and manufactured specifically for our customer applications. These isolators are used to diminish vibration, impact or shock as well as to reduce noise level during application use. Examples of vibration control devices currently being manufactured are listed below.

HEADLIGHT SEALS

A common problem in a headlight systems is moisture penetrating into poorly sealed crevasse and entering into the headlight itself, causing a cloudy appearance. To avoid this, custom seals are added around all the wire fixtures and any other applications where two parts are being joined. To this end, HLN can manufacture custom grommet wire systems, wire pass through grommets and harness plugs. Cable grommets are used with enclosures and panels where the cables entry point must be sealed from moisture and dust.

BRAKES & MODULES

Brakes are one of the most critical parts on an automobile and rubber parts used in such applications need to be able to withstand the extreme environmental conditions, as well as the frictional heat produce from everyday braking.

ENGINE MOUNTS / CHASSIS

Engine mounts are rubber to metal bonded components used to isolate vibration, absorb shock and support load. HLN’s manufactured engine mounts are highly durable and heat resistance.

Many applications in the chassis and underbody systems call for rubber products including, shock absorber seals, CV boots and liners, vibration mounts and air springs, all of which contribute greatly to the smooth driving experience. HLN prides itself to be part of the greater team to contribute to this calling.

HEAD GASKETS

The cylinder head gasket is commonly considered to an important seal in the automotive engine. The Multi-Layer Steel (MLS) gasket is used to seal between the cylinder head and engine block. In this system, multiple layers of cold-rolled spring grade stainless steel are coated with a thin and precise layer of elastomeric material. HLN possess the technology and skilled labour to perform this important coating process. This thin layer of elastomer is essential to the structure by providing a sealing action to the metal surface imperfections, while resisting aggressive gases, oils and coolants.

ENGINE GASKETS

Engine gaskets used in engine applications need to demonstrate high temperature stability. HLN has expertise in these applications including, manifold gaskets, diaphragms and other applications that require custom molded rubber products.

With the trend of engine and powertrain systems pushing sealing materials to their limits, HLN has responded by developing and experiment new formulations that are able to meet these strenuous demands and still be cost efficient, allowing us to offer very competitive pricing.

FUEL SYSTEMS

HLN recognizes the higher demand for passenger safety and tightening controls on emissions, which translates to HLN’s high performance fuel system seals, diaphragms and gaskets. With its formulations and process, HLN can ensure that its fuel system components can function under such stringent automotive emission regulations and increasingly hostile engine compartment environment, and enable system designers to meet near zero fuel permeation targets without compromising on designs.

HVAC & COOLING SYSTEMS

HLN possesses the expertise and experience to manufacture custom seals and sealing devices for automotive HVAC and Cooling Systems. With 40 year of rubber manufacturing experience, HLN engineers and chemists help in the design process as well as in choosing the correct elastomer for the application.

TRANSMISSION SEALS

The automatic transmission is a complex system combining several different applications, posing a challenge for seal designers. HLN works closely and actively with customers on the design, and offers its experience and inputs to promote greater synergy, especially on complex parts and designs.

Typically, two main types of transmission designs inlcude rear wheel drive and front wheel drive, both requiring seals to prevent any leakage. Rear drive designs, for example, employ an input seal to prevent leakage of transmission fluid at the interface between the torque converter and the transmission case. Front drive designs use an output seal to prevent leakage past the output shaft.

BUMPERS

-

Recess Bumpers - providing a cushioning effect and non-skid surface, which can be mechanically fixed using a rivet and screw to its rubber feet

-

Stem Bumpers - inserted into pre-drilled hole to serve as bases for cabinets and small boxes, preventing scratches and keep them from slipping

-

Plug Bumpers - serves as a nipple, or hole plug

-

Screw Bumper - attach the bumpers to the surface using screws

-

Tack Bumper - eliminate sound and are used to protect any surface from damage

-

Grommet Bumper - inserted into a pre-drilled hole with ease and can be used as a rubber feet